Warehouse racks

-

MEDIA EXPERT PL

Relocation of the Shuttle rack system, moving racks with a total capacity of 10,000 pallet spaces. Timeliness was crucial, as the project needed to be synchronized with the transfer of the client’s entire stored inventory. Fortunately, the project was completed in even less time than originally planned. Shuttle racks / Mediaekspert / 10,000 pallet spaces; […]

-

TMA NL

The work involved erecting a complex of 6 independent self-supporting warehouses, which ultimately formed a system capable of holding 37,000 Euro pallets. The port surroundings required constant weather monitoring while operating heavy equipment. To meet the schedule, we deployed a 40-person team. Automated self-supporting warehouse / TMA NL / 37,000 pallet spaces; 2 working aisles […]

-

CYBER IL

One of the most complex projects in our history, where we supervised the installation carried out by local Middle Eastern companies. Coordination took on a whole new meaning here. Perhaps the first warehouse in the world where 70% of the material came from a previous dismantling. The number of engineering modifications required was staggering, with […]

-

PEPSICO PL

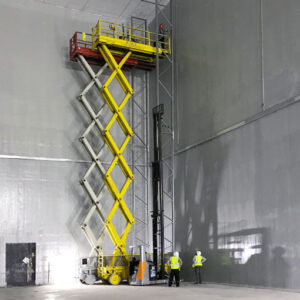

An automated self-supporting warehouse with a significant amount of robotic components, erected in the newly constructed PEPSICO building in Środa Śląska. The installation required compliance with safety standards higher than those mandated by law. The installation was carried out indoors using heavy equipment, necessitating high precision from machine operators. Automated self-supporting warehouse / PEPSICO PL […]

-

MARS PL

Another special installation for MARS, this time in Poland after several installations in foreign branches. The racks are designed for storing special stacks for pet food pouches. The construction is fully automated and maintains the highest corrosion protection standards, required due to frequent system disinfection. Self-supporting automated racks / MARS PL / 1 stacker crane; […]

-

ŻABKA PL

A prototype self-supporting warehouse structure in Poland, 37m high, with a capacity of 30,000 pallet spaces, adapted for storing standard EUR pallets. The warehouse is operated by 6 stacker cranes. The project required adapting work schedules to both summer and winter conditions. The rack structure is just part of a larger, highly innovative technological complex. […]

-

BYGMA DK

A project for our long-term Danish business partner, where we install systems in Denmark annually. This particular installation included a mix of different rack systems: cantilever, pallet, bulk, shelving, and mezzanine. The project required many additional accessories for each of the systems. Various warehouse racks / BYGMA DK / drive-in 400 pallet positions; row racks […]

-

BASF DE

The installation involved erecting two self-supporting structures, each 23m tall, significantly higher than their length (17x8m), within a space limited to installations. An additional challenge was the need to create new safety procedures to meet some of the highest work safety requirements we’ve encountered. Each installation is operated by a horizontal stacker and conveyor system. […]

-

CashCenter EG

This was the second phase of the project in Cairo, which started in May 2015. It was quite an unusual project due to the location of the structure, the principal and the governmental structures of Egypt. For years we have been erecting structures that rise above the surface of the ground. In this particular project, […]

-

Miniload construction, VOSS

Miniload material storage system for boxes (48 720 places for boxes, 4 stacker cranes 10 m height, volume 5 200 m3). The whole, including all necessary settings, had to take 70% of the time normally counted for such a construction, which required the accumulation of a larger team with effective supervision. This allowed for additional […]

-

Warehouse intended for warehouse automation systems

A rack construction supporting the logistics of the Egyptian mint. Installation of 19 m height required high precision due to the very small space to the ceiling, only 5 cm. Works carried out in a concrete room with very difficult access. An additional difficulty was the necessity of organizing all tools on site and cooperation […]

-

Self-supporting warehouse with automated technology

The implementation was based on placing two constructions – a larger one with a capacity of over 15,000 pallet places and a smaller one with approximately 3,000 pallet spaces. The larger installation is remotely served by 5 stackers, smaller by 1. It was one of the higher constructions, with a total height of 39 meters […]

-

Self-supporting warehouse with automated technology

Two separate installations, self-supporting warehouse 31 meters high and the shorter one 11 meters high for production materials. With 6 stocker cranes designed for EUR pallets (20 604 pallet places, 190 pieces of automatic devices). The whole warehouse with wide and automated spaces. The project required the involvement of Polish and German specialists.

-

Pallet racking, Neupack

Typical racking installation for high storage. It required using of appropriate equipment and a number of montage teams because of high (16 metres) and heavy (230 kg) frames. There were 17550 pallet places installed and 900 frames. The work quality was monitored by the surveyor.

-

Pallet racking, Pallet Shuttle, Miniload

The complex investment made of few different installations connected with high automated conveyor systems. Apart from typical racking installation there were also installed: pallet shuttle (2247 pallet places), Miniload (820 pallet places) and 3 stocker cranes (11 meters high). It required the highest precision at setting up the automated technology into big one concept.